SIS Switchboard Cable: Build the Bridge between Power

- Share

- Issue Time

- Aug 4,2025

Summary

Discover industrial-grade switchboard SIS cables with XLPO insulation for harsh environments. Learn key specs, applications in solar farms/data centers, and compliance with CSA/NEC standards. Ensure 25+ year reliability – download our cable selection guide.

Definition and Function of Switchboard Cable

Switchboard SIS cable is a type of cable specifically designed for power distribution and control systems. Its primary function is to facilitate safe and efficient power transmission between switchboards, control panels, and various electrical equipment in industrial, commercial, or renewable energy projects. The key distinction between switchboard cable and other cable types lies in its XLPO insulation, which protects the wires from moisture, chemicals, and high temperatures.

The core functions of switchboard cable include power transmission and signal transmission. The commonality between both is that they aim to ensure stable and reliable power supply to all connected devices throughout the process. During power transmission, it carries electrical current from a central power source (such as a transformer or distribution board) to devices like circuit breakers, relays, and terminal blocks. During signal transmission, the switchboard cable is also responsible for carrying control signals and data. This enables precise monitoring, automation, and coordination of equipment, especially within complex electrical systems like solar power plants, production lines, or data centers.

Types of Switchboard Cable

a. Power Cables

In solar farms covering vast areas, power cables serve as the backbone of the distribution system, primarily responsible for power distribution. They aggregate and transmit the electricity generated by PV modules from numerous local combiner boxes to central units (such as inverter cabinets and the main switchboard), forming an efficient power transmission path.

b. Control Cables

Control cables play a central role in control, automation, and protection circuits within solar farms. They connect equipment like inverter cabinets, monitoring units, the main switchboard, and protective relays. They are specifically designed to transmit low-voltage control signals required for real-time data collection, remote diagnostics, and fault detection, as well as critical command signals that trigger safety shutdowns, isolation, and grounding in the event of a system fault.

c. Instrumentation Cables

Instrumentation cables focus on precise signal monitoring in solar farms. They are primarily used to connect various sensors (such as temperature sensors, irradiance sensors) and monitoring instruments distributed throughout the plant. They transmit the collected low-voltage analog or digital signals (e.g., environmental parameters, equipment status, power generation data) to monitoring units with low loss and minimal distortion, providing fundamental data for plant performance evaluation, fault warning, and operational optimization.

Key Characteristics of Switchboard Cable

Physical Characteristics of Switchboard Cable

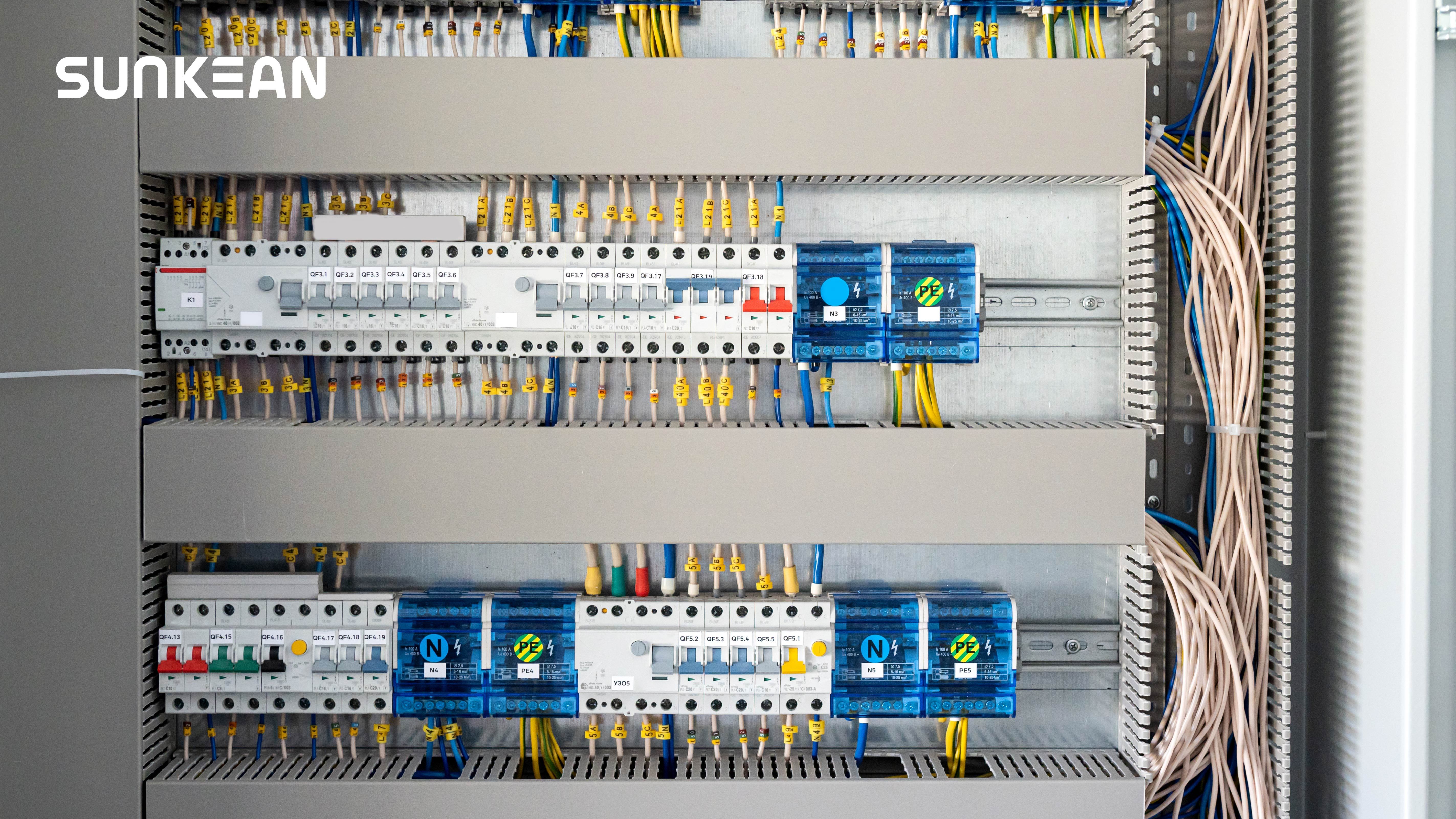

a. Flexibility in Confined Spaces

Given that switchboard layouts often involve confined spaces (like compact cabinets), dense wiring within them frequently employs cables combining fine-stranded copper conductors with flexible insulation materials. This type of switchboard cable offers sufficient flexibility during installation, allowing it to navigate tight bends and maneuver around other components easily. This characteristic simplifies both installation and subsequent modification steps, reduces mechanical stress on terminals and cable entry points, and helps maintain a neat and orderly overall panel layout.

b. Mechanical Strength

Considering that switchboard cables must endure frequent physical stresses like dragging, pulling, sharp bends, and twisting during installation, high mechanical performance is crucial. Premium switchboard cables utilize cross-linked polyolefin materials, featuring robust insulation with resistance to abrasion and crushing, along with adequate tensile strength. This effectively prevents the insulation of the switchboard cable from cracking or degrading.

c. Compatibility with Terminals and Connectors

Given that switchboard systems involve a wide variety of terminal blocks, lugs, and connectors, switchboard cables must be compatible with these termination devices. This requires precise cable sizing to match standard equipment, good strippability for clean insulation removal without damaging the internal conductor, and adaptability to connection methods like crimping or screw clamping based on the specific switchboard design. This effectively mitigates risks such as loose terminals or contact failures.

Chemical Characteristics of Switchboard Cable

a. Flame Retardancy and Smoke Emission Ratings

In enclosed environments like control panels and data centers, cable safety heavily depends on its fire performance. High-quality switchboard cable must therefore meet stringent flame retardancy and low smoke emission requirements, such as compliance with fire safety standards from authorities like IEC 60332, UL VW-1, or FT1. It also employs low-smoke zero-halogen (LSZH) materials to reduce smoke emission and avoid releasing toxic halogen gases. These properties work together to prevent fire spread, protect nearby equipment, and enhance personnel safety, making them vital for compliance with fire codes and industrial safety regulations.

b. Heat and Moisture Resistance

Switchboard cables often need to operate reliably in high-temperature environments (e.g., near inverters or heavy machinery) and may be exposed to condensation, humidity, or corrosive particles/salts in poorly ventilated cabinets within industrial zones or coastal locations. Therefore, switchboard cable should maintain stable performance at high temperatures, preserve insulation integrity under humid conditions, and effectively resist chemical corrosion. This extends cable service life and reduces the risk of insulation failure or short circuits.

Common Applications of Switchboard Cable

Switchboard Cable in Large-Scale PV Projects

a. Power Plants and Substations

Electricity generated by PV modules is collected and conveyed to inverter stations and step-up substations, ultimately connecting to the grid. Throughout this process, switchboard cable is widely used to connect control cabinets and distribution boards. It transmits power between inverters, switchgear, transformers, and monitoring systems, while also ensuring reliable signal transmission for protective relays, sensors, and communication equipment automation. These environments often involve high currents, intense UV exposure, significant temperature fluctuations, and mechanical stress. Certified switchboard cable is specifically designed to withstand such demanding conditions.

b. Renewable Energy Power Plants

In renewable energy power plants like solar farms covering extensive areas, switchboard cable is a critical component connecting local combiner boxes, inverter cabinets, monitoring units, and the central switchboard. Its core functions encompass: Power Distribution – transmitting power from multiple PV strings to central units; Control & Automation – carrying low-voltage signals for real-time data collection, remote diagnostics, and fault detection; and Protection Circuits – enabling safety shutdowns, isolation, and grounding during faults.

Switchboard Cable in Small Factory Projects

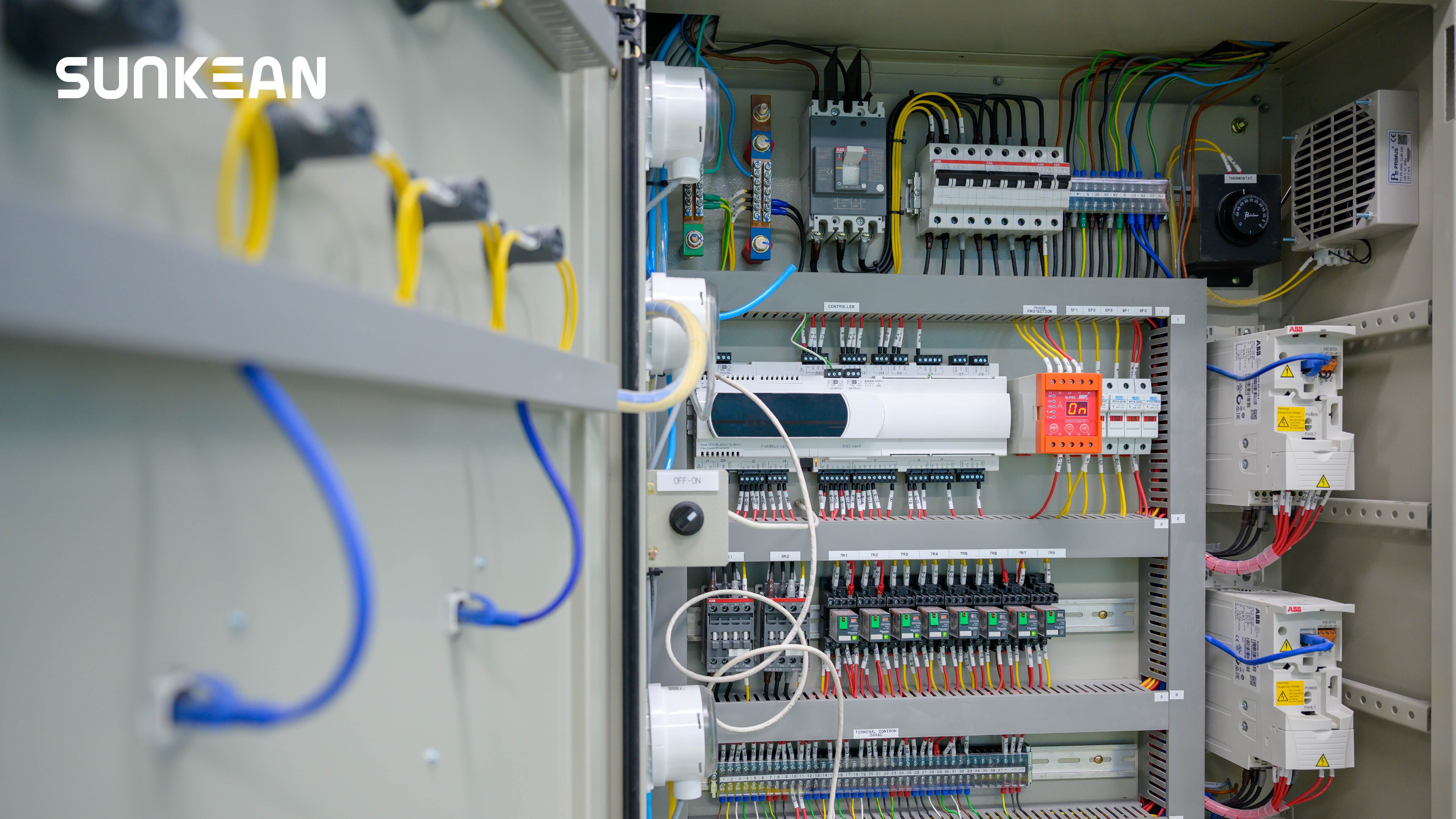

a. Factory Control Panels

In small manufacturing or processing plants, control panels act as the nerve center for managing equipment like motors, lighting, conveyors, and HVAC systems. Switchboard cable used in these environments must possess excellent flexibility, reliable insulation properties, and resistance to vibration and high temperatures. Especially in areas with heavy machinery, this cable connects power relays, contactors, Programmable Logic Controllers (PLCs), and terminal blocks, playing a vital role in automation and production control.

b. Data Centers

Data centers require continuous uptime and high-quality power supply. Switchboard cable meets the need for stable power distribution by connecting Power Distribution Units (PDUs), control systems, and interfaces to backup power sources (UPS and generators).

FAQ: Switchboard & SIS Cable Solutions

Q1: What is switchboard SIS cable?

A: Switchboard SIS cable is engineered for power distribution and control systems, featuring robust XLPO insulation to ensure safe power transmission between switchboards, control panels, and electrical equipment in industrial/commercial/renewable energy projects.

Q2: How does switchboard cable differ from standard cables?

A: Its key distinction is XLPO insulation that resists moisture, chemicals, and high temperatures – critical for harsh environments like solar farms or data centers.

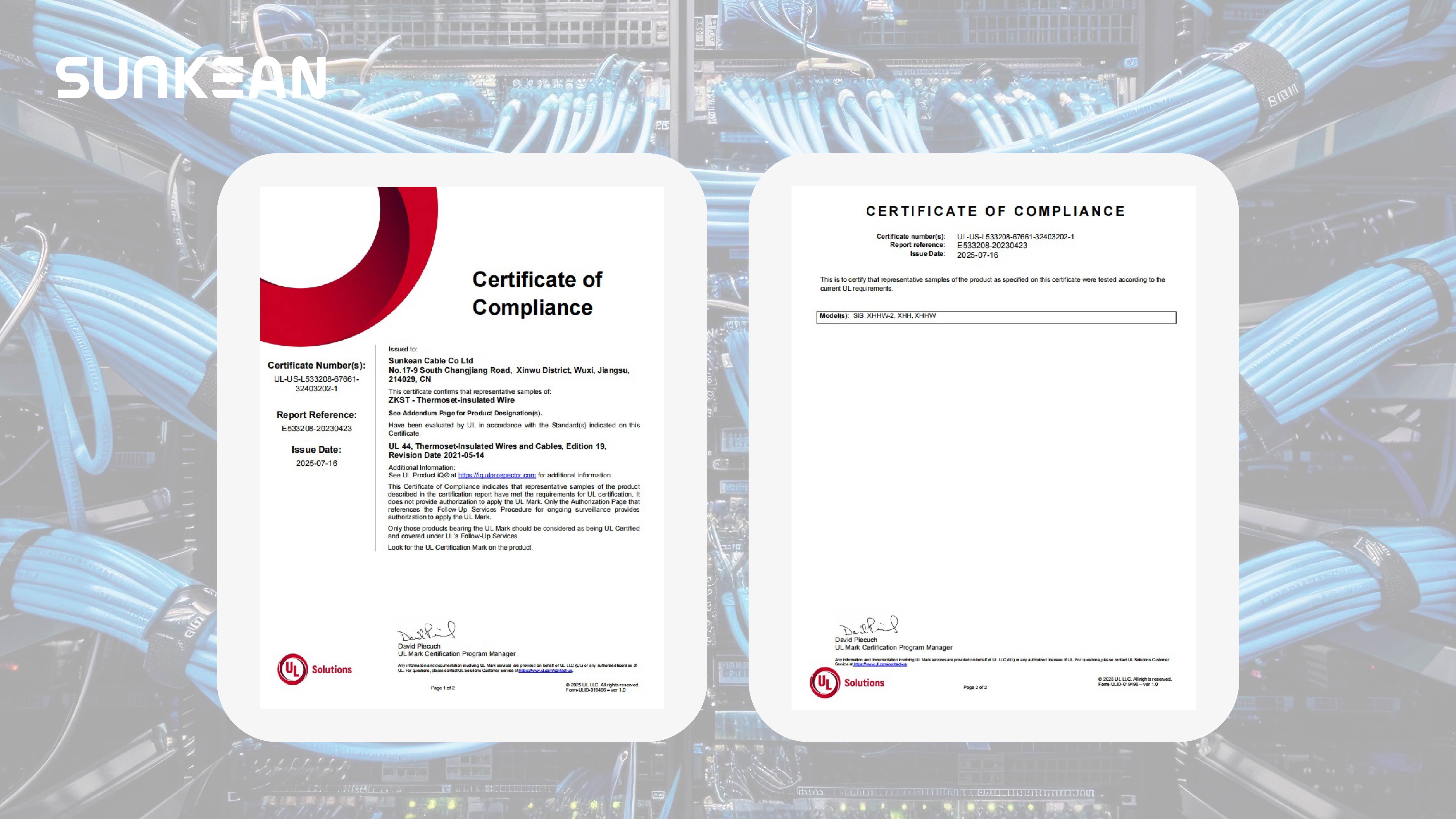

Q3: What certifications do switchboard cables require?

A: They must comply with CSA C22.1 (Canada), NOM-001-SEDE (Mexico), and NFPA 70 (US), covering voltage ratings, flame retardancy, and environmental resilience.

Q4: Why use switchboard cables in solar farms?

A: They enable efficient power aggregation from PV modules to inverters (via power cables), real-time monitoring (via control/instrumentation cables), and fault protection – all while withstanding UV, heat, and mechanical stress.

Q5: Can switchboard cables handle high-temperature environments?

A: Yes. Premium switchboard cables (e.g., UL XHHW XLPE) maintain stability near heat sources like inverters or heavy machinery, with thermal resistance up to 90°C.

Q6: Are these cables suitable for confined spaces?

A: Absolutely. Flexibility from fine-stranded copper and flexible insulation allows easy routing in compact switchboards, reducing installation stress and space constraints.

Q7: Do switchboard cables support fire safety?

A: Critical for enclosed spaces. Top-tier options meet IEC 60332/UL VW-1/FT1 flame ratings and use Low-Smoke Zero-Halogen (LSZH) materials to limit toxic smoke.

Q8: What applications use control vs. instrumentation cables?

A: Control cables transmit automation signals (e.g., relay commands); instrumentation cables handle precision sensor data (e.g., temperature/irradiance readings) with minimal signal loss.

Q9: How long do switchboard cables last?

A: Lifespan exceeds 25 years when certified for moisture/chemical resistance – vital for renewables, factories, and coastal installations.

Q10: How to choose the right switchboard cable?

A: Prioritize: ① Compliance with regional electrical codes, ② XLPO/XLPE insulation for durability, ③ LSZH for safety, and ④ Flexibility/abrasion resistance for your installation environment.