Which cable material is suitable for you project?

- Share

- Issue Time

- Oct 18,2024

Summary

How much do you know about XLPE, XLPO and PVC? What are the differences between them?

Ⅰ. Introduction

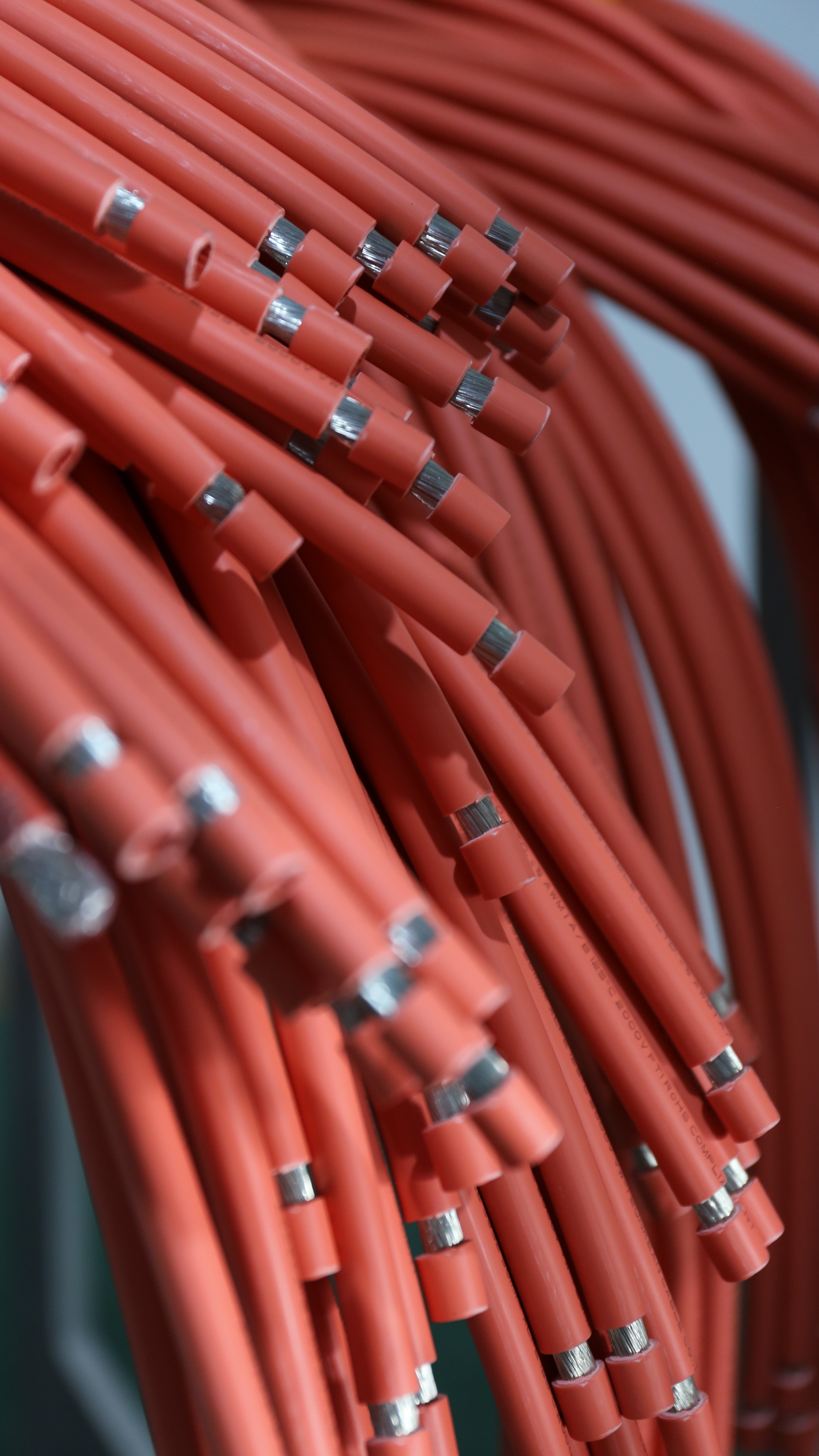

Solar cables are responsible for carrying electrical energy generated by solar panels to other components, such as inverters and batteries. They are constantly exposed to a range of environmental conditions, from intense sunlight and high temperatures to rain, wind, and even extreme cold. The insulation and sheathing materials used in solar cables must be able to withstand these conditions to prevent energy loss, protect against short circuits, and avoid potential hazards like fires or electrical shocks. Furthermore, durable materials contribute to the longevity of the solar installation, reducing the need for frequent maintenance or replacements, which can be costly and time-consuming.

Among the most common materials used in solar cable insulation and sheathing are Cross-Linked Polyolefin (XLPO), Cross-Linked Polyethylene (XLPE), and Polyvinyl Chloride (PVC). Each of these materials has its own set of properties that make it suitable for different environmental conditions and project requirements.

In this post, we'll explore the characteristics, strengths, and limitations of XLPO, XLPE, and PVC. We'll discuss how each material performs under various conditions and provide insights into their ideal use cases, helping you make an informed choice for your solar power system.

Ⅱ. Overview of XLPO, XLPE, and PVC

XLPO (Cross-Linked Polyolefin): This is a durable, versatile material commonly used in solar cable insulation and sheathing due to its superior flexibility, UV resistance, and thermal stability. The "cross-linking" process chemically bonds the polymer chains, which significantly enhances the material's resilience and performance under extreme environmental conditions. This cross-linking enables XLPO to maintain its structural integrity and insulating properties even when exposed to high temperatures, making it an excellent choice for outdoor solar applications where cables are subjected to prolonged sunlight and fluctuating weather.

XLPE (Cross-Linked Polyethylene): This is a robust and highly durable material used in solar cable insulation due to its impressive resistance to heat, chemicals, and moisture. Similar to XLPO, XLPE undergoes a cross-linking process that chemically bonds its polyethylene chains, creating a three-dimensional structure. This structure enhances the material's mechanical strength and stability, allowing it to perform well under extreme conditions and making it a popular choice for solar power systems and beyond.

PVC (Polyvinyl Chloride): This is one of the most commonly used materials in cable insulation and sheathing, known for its versatility, affordability, and ease of production. As a thermoplastic, PVC can be easily molded and shaped into a variety of forms, making it ideal for a wide range of applications. In solar power systems, PVC is frequently chosen for cable insulation because it provides adequate protection against general wear and tear while maintaining cost-effectiveness for projects with budget constraints.

Ⅲ. Advantages and Disadvantages of Each Material

A. Pros&Cons of XLPO

Excellent Flexibility: XLPO is known for its outstanding flexibility, even in cold temperatures. This makes it easy to install and maneuver around complex layouts, such as rooftop solar panels or ground-mounted arrays.

UV Resistance: XLPO offers high UV resistance, making it ideal for outdoor solar installations where cables are exposed to sunlight. Its ability to withstand prolonged UV exposure ensures long-lasting durability, reducing maintenance and replacement needs.

Good Thermal Properties: XLPO performs exceptionally well under high temperatures, withstanding continuous exposure up to 125°C. Its thermal stability prevents insulation breakdown and maintains consistent performance, even in hot climates or when handling high electrical loads.

Higher Cost Compared to PVC: Due to its enhanced performance and durability, XLPO is generally more expensive than PVC. For projects on a tight budget, this may be a limiting factor. However, the initial investment can lead to long-term savings by reducing maintenance and replacement costs.

B. Pros&Cons of XLPE

High-Temperature Tolerance: XLPE has excellent thermal stability and can handle continuous temperatures up to 90°C, with the ability to resist short-term surges up to 250°C. This makes it ideal for solar installations where cables may be exposed to fluctuating temperatures and high electrical currents.

Resistance to Wear and Chemicals: XLPE is highly resistant to abrasion, chemicals, and environmental stressors. This durability makes it suitable for outdoor solar applications, as it can withstand harsh conditions, including exposure to oils, solvents, and other chemicals that may be present in certain installation environments.

Long-Lasting Durability: The cross-linked structure of XLPE enhances its mechanical strength and resilience, ensuring long-lasting performance. This makes XLPE cables less prone to physical damage, extending the life of the solar installation and reducing the need for frequent replacements.

Less Flexible than XLPO: While XLPE offers some flexibility, it is not as pliable as XLPO. This may make it slightly more challenging to handle during installation, particularly in setups with tight bends or complex layouts where higher flexibility is necessary.

Can Be More Expensive than PVC: Although XLPE is typically less expensive than XLPO, it still costs more than PVC.

C. Pros&Cons of PVC

Cost-Effective: PVC is one of the most economical options for cable insulation and sheathing, making it a popular choice for solar installations with budget constraints. Its affordability allows for reduced initial costs, which can be beneficial for large-scale projects or installations in areas with limited funding.

Widely Available: PVC is a widely used and readily available material, making it easy to source from most cable suppliers. This availability often results in shorter lead times for procurement, allowing for faster installation timelines.

Good Overall Durability: PVC provides reliable protection in moderate environmental conditions. It offers decent resistance to general wear and tear, moisture, and basic environmental factors, making it a suitable option for indoor solar systems or sheltered outdoor installations.

Lower Temperature Resistance: Compared to materials like XLPO and XLPE, PVC has a limited temperature tolerance, typically up to around 75°C. Prolonged exposure to higher temperatures can lead to softening or deformation, which may compromise the cable's integrity and insulation properties.

May Degrade Faster Under UV Exposure: PVC is more susceptible to degradation from UV radiation than XLPO and XLPE. When exposed to direct sunlight over long periods, PVC can become brittle, crack, and lose its insulating effectiveness. This reduced UV stability makes it less suitable for outdoor solar installations unless additional protective sheathing is used.

Ⅳ. Ideal Use Cases for XLPO, XLPE, and PVC in Solar Cables

A. XLPO (Cross-Linked Polyolefin)

Best Suited For: Outdoor solar installations that require high flexibility and superior UV resistance.

XLPO's excellent UV resistance makes it an optimal choice for solar systems exposed to intense sunlight, such as rooftop solar panels or open-field solar farms. Its flexibility is advantageous for complex layouts where cables must navigate around obstacles or be frequently adjusted. Additionally, XLPO's durability in extreme weather conditions makes it a reliable option for installations in areas with fluctuating temperatures and exposure to harsh elements.

Example Applications: Large-scale solar farms, rooftop solar panels, and ground-mounted solar arrays in regions with high sun exposure or harsh weather conditions.

B. XLPE (Cross-Linked Polyethylene)

Best Suited For: High-temperature environments and installations requiring chemical resistance.

With its high-temperature tolerance, XLPE is particularly well-suited for solar installations in hot climates or where cables may be subjected to elevated temperatures due to high electrical loads. Its strong chemical resistance is also beneficial in industrial environments or in areas where the cables may be exposed to oils, solvents, or other chemicals. XLPE's balance of durability and cost-effectiveness makes it an excellent choice for most commercial and residential solar projects.

Example Applications: Industrial solar installations, residential or commercial rooftop solar systems in warm climates, and solar systems where cables are routed through potentially corrosive environments.

C. PVC (Polyvinyl Chloride)

Suitable For: Budget-conscious projects or installations in areas with moderate environmental exposure.

PVC's affordability makes it a good choice for solar projects with tight budgets or for large installations where cost savings are a priority. While it is less resistant to UV and high temperatures, PVC can perform well in areas with moderate environmental exposure, such as indoor solar installations or outdoor systems with some level of shading. Its availability and cost-effectiveness make it a viable option for less demanding solar applications where the cables will not be exposed to extreme conditions.

Example Applications: Indoor solar installations, shaded rooftop solar systems, and budget-friendly solar projects in temperate climates with limited sun exposure.

Ⅴ. Related Properties

A. Fire Resistance

XLPO has inherent fire-resistant properties, making it one of the safer options for solar cables. Its cross-linked structure provides enhanced flame retardancy, reducing the risk of combustion and slowing the spread of fire. XLPO is designed to meet stringent fire safety standards, which is why it is often used in high-risk environments. Besides its ability to resist flames, XLPO emits lower levels of toxic fumes when exposed to fire compared to some other materials. This characteristic makes it particularly valuable in solar installations near residential or commercial buildings where safety and air quality are priorities in the event of a fire.

XLPE also exhibits good fire-resistant qualities due to its cross-linked structure, which enhances its stability under high temperatures. However, it may not be as inherently flame-retardant as XLPO and may require additional fire-retardant additives for specific applications. XLPE's ability to resist ignition and slow flame propagation makes it a safe choice for most solar installations. XLPE's fire resistance is complemented by its low smoke emissions, which can be beneficial in enclosed spaces or areas where visibility and air quality are essential during a fire. This feature makes XLPE a practical choice for both indoor and outdoor solar installations where fire safety is a concern.

PVC is naturally flame-retardant and can self-extinguish when the source of ignition is removed. This property makes PVC a commonly used material in applications where fire safety is critical. However, while PVC does resist flames, it can release harmful chlorine gas and dense smoke when it burns, which poses health and safety risks in populated areas. PVC's self-extinguishing property is a valuable feature for low-risk installations, but its release of toxic fumes and dense smoke can be hazardous in fires. For outdoor solar installations, particularly those near residential areas, the potential release of harmful gases may be a disadvantage of PVC compared to more environmentally friendly options like XLPO or XLPE.

B. Toxicity and Environmental Impact

XLPO is relatively low in toxicity, especially when compared to materials like PVC. When it burns, XLPO releases fewer harmful fumes, which reduces health hazards in the event of a fire. Its cross-linked structure also provides enhanced durability, which can help minimize the frequency of replacement and waste generation. XLPO is generally considered environmentally friendly compared to PVC. It does not contain harmful halogens or heavy metals, which can leach into the soil or water if the material is disposed of improperly. However, as a synthetic polymer, it still contributes to plastic waste at the end of its life cycle and is not biodegradable. Some manufacturers are working on making XLPO more recyclable to reduce its environmental footprint.

Like XLPO, XLPE is also relatively low in toxicity. It does not contain halogens, which means that it does not release hazardous chlorine gas or other toxic substances when burned. This makes XLPE a safer option for installations near residential areas, where concerns over air quality and safety are high. Environmental Impact: XLPE's environmental impact is similar to that of XLPO. While it is a durable and long-lasting material, it is not biodegradable. Recycling options for XLPE are limited, though advances in chemical recycling technologies are helping to improve its sustainability. Additionally, its chemical resistance and durability mean that it can remain functional for long periods, reducing the need for frequent replacement and thereby generating less waste over time.

PVC has a higher toxicity level compared to XLPO and XLPE, especially when burned. PVC contains chlorine, and when it combusts, it releases harmful dioxins and hydrochloric acid. These substances pose health risks and can contaminate the air and soil, making PVC a less ideal choice in areas with strict environmental and safety regulations. PVC's environmental impact is significant. Its production process involves harmful chemicals, and it is less environmentally friendly in terms of disposal. PVC does not break down easily, and improper disposal can lead to long-term pollution. Additionally, the release of toxic substances during degradation can harm surrounding ecosystems. Some efforts are being made to recycle PVC, but recycling options are still limited, especially when compared to materials with fewer environmental concerns.

Ⅵ. Conclusion

If you are interested in high-quality cables, and comprehensive after-sales service, welcome to visit SUNKEAN, where there are all kinds of latest cable products you need. If you have any needs, you can leave a message to our salesman, thank you for your coordination. Email: sales@sunkean.com