A Guide to Global PV Cable Certifications: TÜV, UL and International Standards

- Share

- Issue Time

- Nov 5,2025

Summary

Choosing the right photovoltaic (PV) cables for your solar projects is crucial. This guide provides EPCs and investors with a detailed overview of major global PV cable certifications, including TÜV MARK (EN 50618), UL 4703, and standards from key markets such as Japan (JET). Learn how certifications ensure compliance, enhance system security, and improve long-term return on investment.

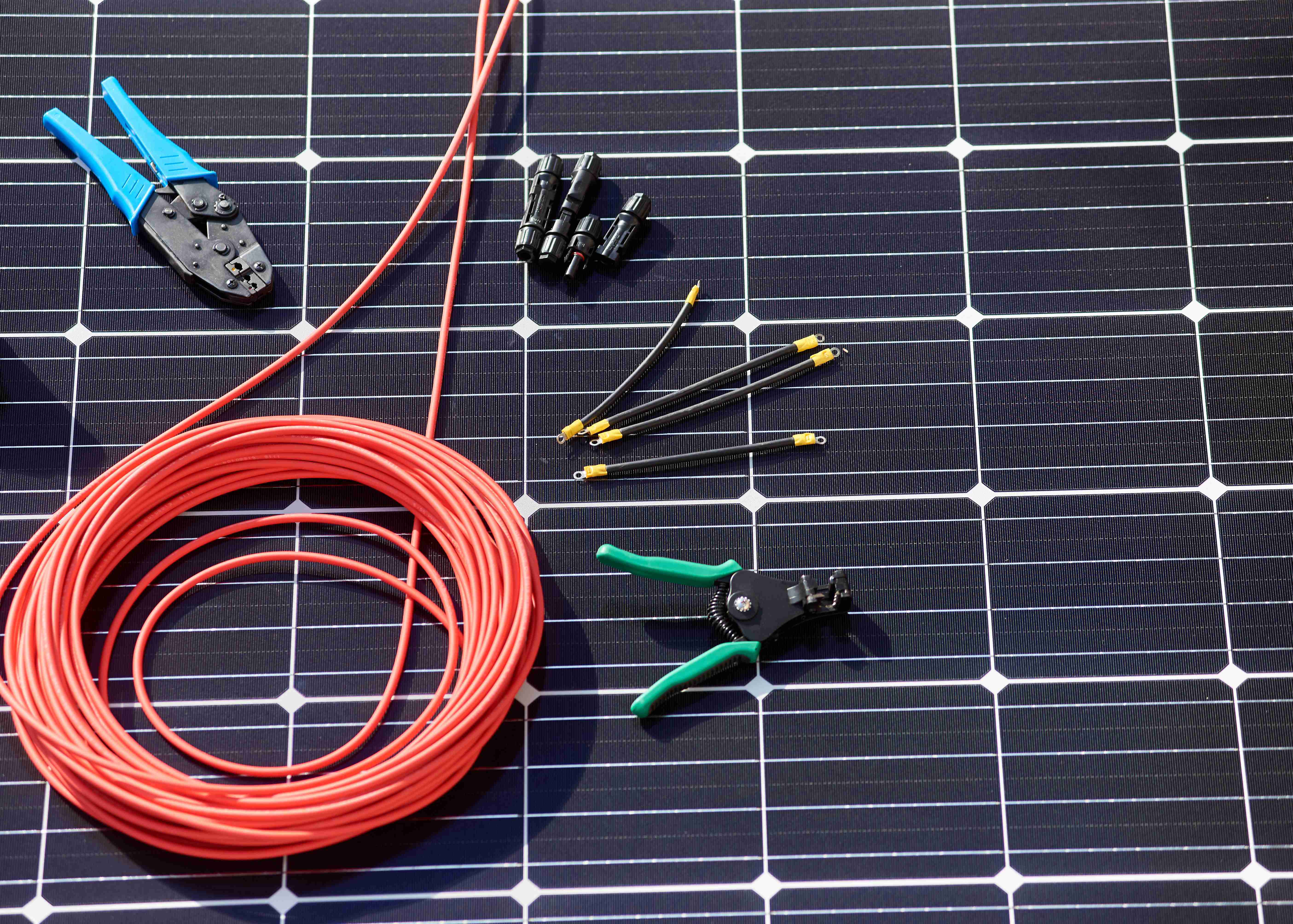

Why Cable Certification Matters in Solar Energy Investments

In a utility-scale solar power plant—a massive capital investment with an operational lifespan exceeding 25 years—the reliability of every single component is intrinsically linked to the project's ultimate return on investment. While modules and inverters often command the most attention, the network of PV cables, acting as the project's "circulatory system," plays an equally critical role. Despite representing a relatively small portion of the overall cost, these cables carry the core mission of energy transmission. Their quality directly dictates system efficiency and long-term safety. Consequently, selecting safe and reliable PV cables is a subject that demands careful consideration from every EPC (Engineering, Procurement, and Construction) contractor and investor. In this critical selection process, understanding globally recognized third-party certification marks becomes the most direct and effective tool for making scientific choices and mitigating potential risks.

The European Benchmark: Understanding TÜV Certification and EN 50618

When we examine the global landscape of PV cable certifications, the German TÜV mark stands out with particular prominence. The TÜV Mark, particularly its flagship standard for PV cables (originally 2 PfG 1169, which has now evolved into the harmonized European EN 50618 standard), is widely regarded as a global benchmark for premium quality. This certification goes beyond basic functionality, enforcing exceptionally rigorous requirements for long-term durability. Cables bearing the TÜV mark are subjected to severe testing for DC voltage endurance, high-temperature resistance (e.g., 120°C), resistance to damp heat, superior UV radiation resilience, and flame retardancy.

This comprehensive testing protocol ensures the cable maintains structural integrity and electrical performance over decades, even when exposed to harsh outdoor climates. For any project targeting the European Union market or high-standard international tenders, TÜV-certified cables are often a mandatory passport for entry, providing assurance of unparalleled long-term performance and reliability.

The North American Standard: UL 4703 and Safety-First Certification

Across the Atlantic, the North American market is authoritatively governed by the UL certification and its standard, UL 4703. While also concerned with performance, the UL philosophy places a paramount emphasis on the mitigation of fire and electrical safety risks. The UL 4703 standard provides the authoritative specification for PV cables in this region, detailing requirements for voltage withstand, heat resistance (typically 90°C or 125°C wet/dry), and crucially, flame propagation characteristics, as verified by stringent vertical flame tests. This intense focus on safety is not merely a recommendation; UL certification is very often a mandatory prerequisite for cables to comply with the National Electrical Code (NEC) and gain acceptance for interconnection with the North American grid. Therefore, for projects in the United States and Canada, sourcing UL-listed cables is an indispensable and non-negotiable step in the procurement process.

Beyond Europe and North America: Key Standards in Growing Global Markets

However, a truly global project perspective requires looking beyond Europe and North America. Major solar markets around the world have developed their own certification frameworks, making "market-first" analysis crucial.

For example, RETIE (Electrical Installation Technical Regulation) is a mandatory national technical regulation in Colombia. This certification aims to establish measures to ensure the safety of human, animal, and plant life, protect the environment, and prevent, minimize, or eliminate electrical risks. It is an essential standard for exporting photovoltaic cables to Colombia.

In Japan, the JIS C 3666 standard for PV cables is critically important. Furthermore, the JET (Japan Electrical Safety & Environment Technology Laboratories) and PSE certification and the associated S-Mark are highly respected indicators of quality and safety, often requested by project developers and utilities to ensure reliability in a market with unique technical requirements.

Strategic Selection: Balancing Market Compliance and Long-Term Value Investment

Faced with these diverse and regionally specific certification frameworks, how should EPCs and investors make astute decisions? The core logic rests on two pillars: "Market Compliance" and "Value Investment."

The primary and non-negotiable driver is the project's location, which dictates mandatory certification requirements. Sourcing cables for a project in Wisconsin requires UL listing; a plant in Portugal demands compliance with EN 50618 (often evidenced by TÜV); and an installation in Karnataka, India, must use BIS-certified products. There are no shortcuts here—failing to comply with local mandatory certifications can lead to failed inspections, project delays, and even invalidated insurance.

The second, more strategic consideration is Value Investment. For projects in regions without stringent mandatory requirements, or for developers with an extreme pursuit of long-term reliability, opting for cables with dual or multiple top-tier certifications (e.g., both TÜV and UL) is a wise strategy. This choice signifies an investment in the plant's entire 25-year lifecycle. A cable that has passed the intense durability testing of TÜV and the rigorous safety tests of UL offers a significantly higher assurance of performance and reduced risk. This proactive approach minimizes the potential for costly downtime, maintenance, and replacement, thereby protecting the asset's long-term profitability and securing financing.

Conductor: 1×1.5~400mm²

Insulation Color: Optional color

Jacket Color: Optional color

Conductor: 1×2.5~400mm²

Insulation Color: Black

Jacket Color: Black

Conductor: 2.5~6mm²

Color: Black, red or other colors

Conductor: 2~8mm²

Insulation Color: White

Jacket Color: Black & white

Conclusion: Certification as a Cornerstone of Solar Project Success

In conclusion, understanding and strategically utilizing these global certifications is far more than a simple compliance exercise. It is a fundamental strategic activity that ensures the safety, efficiency, and long-term profitability of a solar power investment. By aligning procurement with both market mandates and a value-investment philosophy, EPCs and investors can build solar assets that are not only compliant today but also resilient and profitable for decades to come. If you would like to learn more about SUNKEAN's successful large-scale photovoltaic projects, please feel free to visit our website.