The Importance of UV resistance to Solar Cable

- Share

- Issue Time

- Jan 10,2025

Summary

Selecting the right UV-resistant photovoltaic (PV) cable is critical to ensuring the long-term performance, safety, and reliability of your solar energy system. Learn more about the importance of UV resistance for cables.

The Growing Importance of Solar Energy and The Role of Photovoltaic (PV) Systems in Renewable Energy Generation

The world today is in greater need of renewable energy than ever before. As climate change accelerates and fossil fuel reserves dwindle, the need for clean, sustainable energy has become a global priority. Solar energy, one of the most abundant and accessible renewable sources of energy, is at the forefront of this shift. Harnessing solar energy offers an environmentally friendly solution to reducing greenhouse gas emissions and combating climate change, while meeting the energy needs of modern society.

Photovoltaic (PV) systems are the backbone of solar energy production. Using solar panels to convert sunlight directly into electricity, these systems offer an efficient and scalable way to generate electricity. From residential rooftops to large solar farms, PV systems are now ubiquitous around the globe, making a significant contribution to the world's energy mix. In fact, the International Energy Agency (IEA) predicts that solar energy will account for nearly half of global energy capacity by 2050.

However, the effectiveness of a PV system depends on more than just the quality of the solar panels themselves. From the inverter to the mounting structure, each component plays a critical role in ensuring optimal performance. Among these components, PV cables often go unnoticed, but are essential for transmitting the electricity generated by the solar panels to the rest of the system.

Because PV systems are often installed in outdoor environments, these cables are subject to harsh conditions, including strong sunlight, extreme temperatures, and fluctuating weather patterns. This makes the quality and durability of PV cables a critical factor in the overall reliability and efficiency of solar energy systems. In particular, their resistance to ultraviolet (UV) radiation is critical to ensuring long-term performance, safety, and cost-effectiveness.

What is UV resistance?

A. What is UV radiation?

Ultraviolet (UV) radiation is a form of electromagnetic radiation that comes from the sun and artificial sources like welding torches and tanning beds. It falls within the spectrum of light, just beyond visible violet light, with wavelengths ranging from 100 to 400 nanometers. While UV radiation is invisible to the human eye, it has powerful effects on materials, living organisms, and environmental systems.

There are three primary types of UV radiation:

· UVA (320–400 nm): The longest wavelength UV radiation, which penetrates deeper into materials and is the least energetic.

· UVB (280–320 nm): Medium-wavelength UV radiation that is more energetic and causes significant damage to materials and living tissues.

· UVC (100–280 nm): The shortest wavelength and most harmful UV radiation. Fortunately, UVC is almost entirely absorbed by Earth’s atmosphere and doesn’t reach the surface.

In the context of solar power systems, UV radiation from the sun poses a major challenge to materials exposed to the elements, including photovoltaic cables. Prolonged exposure to UV rays can lead to material degradation, such as discoloration, brittleness, and cracking. These effects are especially pronounced in plastic and rubber components, which make up the insulation and sheathing of cables.

UV resistance refers to a material's ability to withstand the damaging effects of UV radiation over time. In photovoltaic cables, this resistance is critical to maintaining their structural integrity and electrical performance in outdoor environments. Without proper UV resistance, cables can deteriorate quickly, leading to reduced system efficiency, higher maintenance costs, and even safety risks.

B. How does UV radiation damage cables over time?

When UV radiation penetrates the surface of a cable's insulation, it breaks down the molecular bonds in polymers like polyethylene, polyvinyl chloride, or rubber. This degradation can lead to:

a. Brittleness: The material loses its flexibility, making it more susceptible to cracking under pressure. Over time, the loss of elasticity due to UV exposure can cause cracks and fissures in the cable jacket. These cracks allow moisture, dust, and other contaminants to enter, increasing the risk of electrical failure and corrosion.

b. Surface erosion: The outer layer of the insulation becomes frayed and rough due to the breakdown of the polymer surface. This erosion weakens the cable's ability to protect it, making internal components more vulnerable to environmental factors such as moisture and dust.

c. Discoloration: The surface of the cable may fade, turn white, or take on a white powdery appearance, which is a clear visible indicator of UV damage. Discoloration often indicates that the structural integrity of the material has been compromised.

C. Degraded Insulation

Damage to the insulation caused by UV rays can compromise its dielectric properties. This means that the cable becomes less effective at preventing leakage, leading to:

a. Power loss: Degraded insulation quality allows current to escape, reducing system efficiency.

b. Short Circuits: Damaged cables can create unsafe electrical pathways that can cause equipment failure.

c. Safety Hazards: Exposed or degraded insulation can increase the risk of electric shock or fire.

D. Accelerated Aging

UV radiation can significantly accelerate the aging process of cables, shortening their service life. While high-quality PV systems are designed to last more than 25 years, cables that lack proper UV resistance can fail prematurely, leading to frequent repairs and higher long-term costs.

E. Safety and Operational Risks

Damaged cables can pose serious safety and operational risks, including:

a. Fire Hazards: Cracked or brittle insulation can increase the potential for sparks, overheating, and fire.

b. System Downtime: Faulty cables can interrupt the flow of power and reduce the overall efficiency of the system.

c. Expensive Repairs: The need for premature replacement and repairs can increase maintenance costs, reducing the return on investment (ROI) of your solar installation.

Why is UV resistance in cables important?

A. The role of cables in solar energy systems

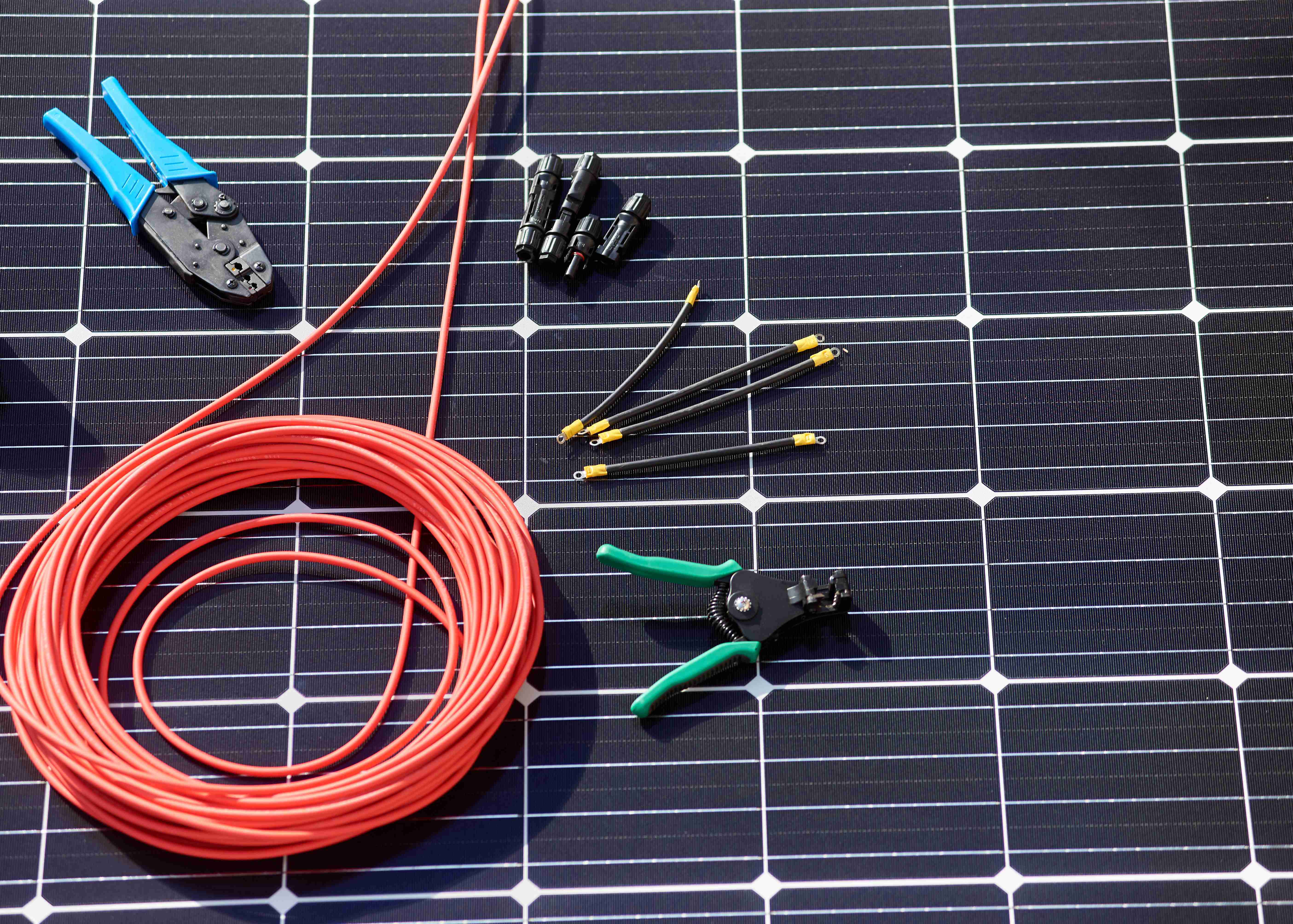

Cables are an essential but often overlooked component of a solar energy system. While solar panels and inverters get most of the attention, cables are the lifeline that connects and powers the entire system. Without them, the energy generated by solar panels cannot flow to the inverter, battery storage, or the grid.

Here are the functions of cables in photovoltaic (PV) systems and why their quality is so important:

a. Power Transmission

PV cables carry the direct current (DC) electricity generated by solar panels to the inverter, where it is converted to alternating current (AC) for use in your home or business. Any interruptions or inefficiencies in these cables can directly affect the energy output of the system.

b. Ensuring Safety and Reliability

Cables are responsible for maintaining safe and reliable energy transmission. High-quality insulation prevents leakage, short circuits, and the risk of fire. Without durable cables, the entire system could face performance issues or safety hazards.

c. Withstanding Harsh Outdoor Conditions

Unlike many cables, PV cables have been exposed to extreme outdoor environments for decades. They are subject to constant sunlight, temperature fluctuations, wind, rain, snow, and even chemicals. In this environment, the sun’s UV radiation is one of the biggest threats to cable life and performance.

Given their critical role, cable selection for solar systems cannot be underestimated. Selecting UV-resistant cables ensures they can withstand decades of sunlight without compromising performance, helping to maximize the efficiency and reliability of your system.

B. How cables are exposed to sunlight

a. Direct Exposure in Open-Air Installations

Most PV systems, whether on rooftops or in large solar farms, involve cables laid in an open-air configuration. These cables are typically routed along switchboard racks, across mounting structures, or suspended in cable trays, where they are directly exposed to UV light for long periods of time each day.

b. Sustained UV Radiation

In many regions, especially those with high solar irradiance, PV systems are installed in areas that receive intense sunlight year-round. This sustained UV radiation can gradually break down the outer insulation of the cables, causing wear and tear if the materials are not UV-resistant.

c. Reflected and Concentrated Light

In some cases, sunlight reflected from solar panels or nearby surfaces can exacerbate the exposure to which the cables are subjected. The combination of direct UV radiation and reflected light can further accelerate degradation of cables that lack proper UV resistance.

How do I choose the right UV-resistant PV cable?

Conductor: 2.5~6mm²

Color: Black, red or other colors

Conductor: 12AWG~2000kcmil

Color: Black, red or other colors

Conductor: 1×1.5~400mm²

Insulation Color: Optional color

Jacket Color: Optional color

Conductor: 2×1.5~35mm²

Insulation Color: Optional color

Jacket Color: Optional color

Selecting the right UV-resistant photovoltaic (PV) cables is critical to ensuring the long-term performance, safety, and reliability of your solar energy system. While UV resistance is a key factor, there are several other factors to consider when choosing the best cable for your specific needs. The following guide can help you with this process.

A. Materials and Standards

The materials used in the construction of PV cables play an important role in their UV resistance and overall durability. Common materials used for UV-resistant cables are cross-linked polyethylene (XLPE) and cross-linked polyolefin (XLPO).

B. Certifications and Compliance

When selecting UV-resistant cables, it is critical to ensure that they meet industry standards and certifications to guarantee their performance and safety. Look for cables that meet relevant international and regional standards.

C. Temperature Rating

PV cables must be able to withstand extreme temperatures, from cold winters to hot summers. Choose cables with the appropriate temperature rating to ensure they will perform in the specific climate where your solar energy system will be located. Typically, cables designed for outdoor use have a temperature range of -40°C to +90°C or higher.

Willing to answer related questions for you: sales@sunkean.com