UL3817 Energy Storage Cable—The 3000V Voltage Safety Guardian

- Share

- Issue Time

- Jul 1,2025

Summary

The UL3817 energy storage cable, with its 3000V rated voltage and 125℃ rated temperature, stands out as the top choice for high-voltage energy storage projects.

Why we need UL3817 Energy Storage Cable?

The catastrophic April 2021 fire at Beijing's Fengtai District energy storage station—triggered by a short-circuit fault that ignited flammable gases racing through 68 meters of underground cable trenches—resulted in four fatalities and ¥19.68 million ($2.8M) in losses, serving as a grim exclamation point on a global pattern: as energy storage deployments surge with over 350% growth in 100MWh+ projects since 2020, similar incidents from Arizona to South Korea consistently trace failures to conventional cables unable to withstand ESS operating extremes. This vulnerability stems from fundamental mismatches—where standard PVC insulation deforms above 90°C while battery thermal runaway, and 600V-rated wiring collapses under modern 800-1500V DC systems—turning cable trenches into explosive channels. Within this context, UL3817-certified energy storage cables emerge as the engineered solution, specifically designed with 3000V AC ratings and 125°C-rated electron-beam crosslinked XLPE insulation to contain the exact failure modes witnessed at Fengtai: halting flame propagation through trenches, preventing conductor oxidation with tinned copper barriers, and resisting electrolyte corrosion, thereby transforming cable selection from technical preference to critical liability management in gigawatt-scale renewable projects.

Structure of the UL3817 Energy Storage Cable

Functioning as the critical neural network bridging battery cells, BMS controllers, and power conversion systems, SUNKEAN's UL3817 energy storage cable embodies a molecular-level safety philosophy where conductor and insulation materials undergo rigorous defense-focused engineering:

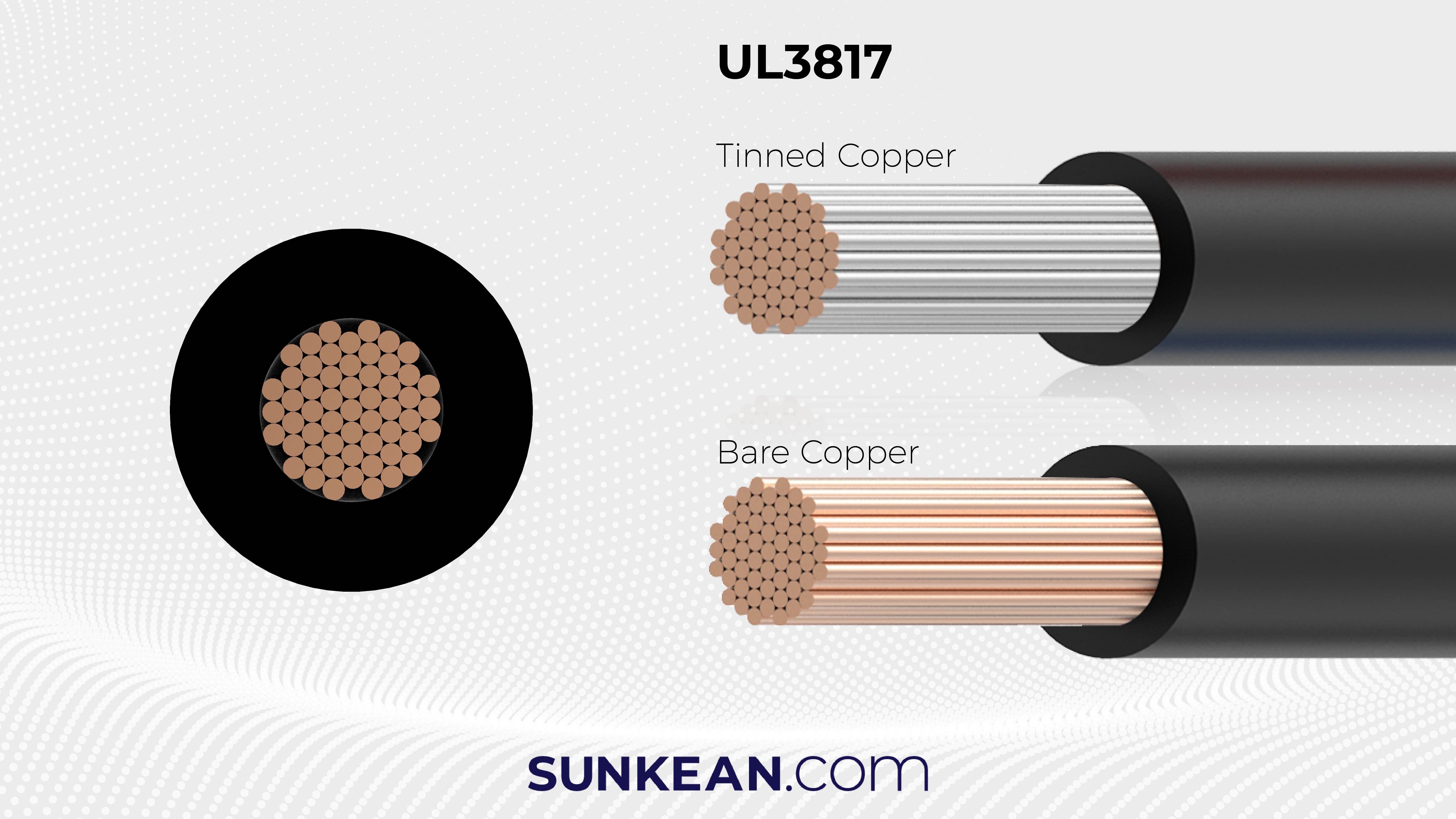

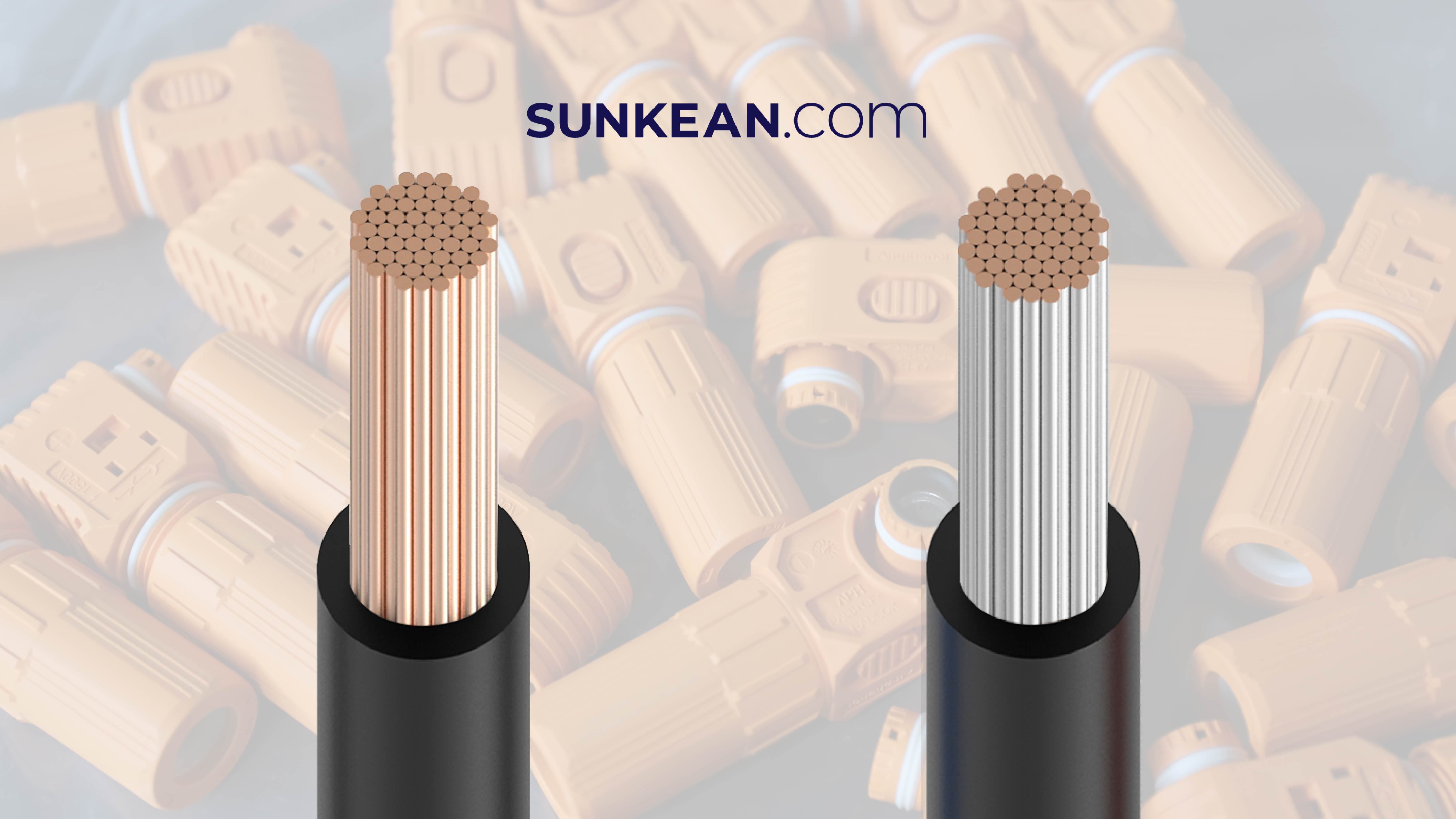

· The conductor employs high-purity tinned copper wire—or optionally bare copper for cost-sensitive applications—precisely stranded via international-compliant processes to cover an unprecedented 30AWG to 2000kcmil range

· Enabling kiloampere current transmission

· Eliminating vibration-induced fatigue fractures through helical flexibility

· The insulation revolutionizes traditional PVC by implementing electron-beam irradiated cross-linked polyethylene (XLPE), where polymer chains create covalent bonds between molecular strands, transforming linear structures into three-dimensional networks that deliver quantifiable performance leaps

· 125°C thermal stability (vs. PVC's 90°C deformation threshold), 3000V rated voltage, UL VW-1 flame retardancy with <50% flame spread distance versus PVC, and halogen-free toxicity profiles

· Achieving chemical resistance against sulfuric/phosphoric acid exposure mimicking battery electrolyte leaks

Characteristics of the UL3817 Energy Storage Cable

The synergy between the conductor and insulation creates a "Conduction - Heat Insulation - Flame Retardation" triple synergy within the UL3817 energy storage cable.

Firstly, the XLPE material endows the cable with a 125℃ high-temperature resistance, providing a thermal barrier for the tinned copper conductor. This avoids fire accidents caused by conductor overheating and melting or battery short circuits.

Secondly, even in the event of battery thermal runaway releasing hydrogen or methane, the halogen-free and low-toxicity properties of the XLPE material prevent toxic gas compounding and cut off the path for fire spread along the trench.

Finally, the XLPE material's aging-resistant design extends the cable's service life, reducing replacement costs caused by cracking and oxidation.

The product design of the UL3817 energy storage cable is a microcosm of the energy storage industry's safety logic—using material innovation to contain risks at the "first mile" of energy transmission. Choosing a cable that resists fire from the source might be the core pathway to safeguarding a project's safety baseline and maximizing the avoidance of fire accidents.