How Aluminum Cables Help Rebuild Stolen Photovoltaic Projects?

- Share

- Issue Time

- Sep 5,2025

Summary

Discover how aluminum PV cables offer a cost-effective, theft-resistant solution for solar project retrofits. Cut costs, boost ROI, and ensure long-term reliability.

Background of Frequent Copper Cable Theft Incidents in Photovoltaic Projects

Copper cable theft has become a serious issue in the photovoltaic industry. As an excellent alternative to copper cables, aluminum cables can help quickly rebuild PV projects. This article details how aluminum cables play a key role in photovoltaic systems. Against the backdrop of frequent copper cable thefts, growing global demand for copper and its high resale value have made PV projects under construction or operation increasingly attractive to thieves. Copper cable theft not only causes significant economic losses but also disrupts power generation at solar installations, leading to project delays and safety hazards.

In many cases, older solar farms installed years ago primarily used copper cables due to their excellent conductivity and durability. However, as these systems age, monitoring and on-site security may lag, making them vulnerable to opportunistic theft. Repairing stolen copper connections is both expensive and time-consuming. Replacing stolen copper cables with new ones entails high material costs and long lead times, resulting in prolonged project downtime. Moreover, copper cable theft does not only affect project owners. Local grids relying on these PV projects may face intermittent power supply issues, and insurance claims can become complicated and costly. Consequently, the photovoltaic industry is increasingly exploring alternative solutions to mitigate these risks while maintaining system efficiency.

Aluminum cables have emerged as a practical and cost-effective alternative. They offer a low-risk, economically viable option for rebuilding or upgrading PV projects after copper cable theft. In addition to cost savings, aluminum is lighter and easier to handle, enabling faster installation, reduced downtime, and lower labor costs. By adopting aluminum cables, project owners can not only quickly restore stolen systems but also safeguard their PV installations against future theft incidents. Aluminum strikes a balance between performance, cost, and theft resistance, making it an ideal choice for restoring damaged solar projects.

Background of Rising Costs for Copper Photovoltaic Cables

Over the past decade, copper has been the most widely used conductor material in photovoltaic cables due to its excellent conductivity, mechanical strength, and long-term reliability. However, driven by multiple factors, global copper market prices have risen significantly, directly impacting the cost structure of solar projects.

First, global demand for copper has surged due to the expansion of renewable energy, electric vehicles, and infrastructure projects. As countries strive to achieve carbon neutrality, copper has become a critical raw material for the energy transition. Sustained demand has pushed copper prices to historic highs, placing substantial cost pressure on PV developers and EPC contractors. Second, supply chain challenges and geopolitical uncertainties have further exacerbated price volatility, with mining production often struggling to keep up with demand. For solar developers with fixed project budgets and thin profit margins, these fluctuations make financial planning increasingly difficult.

Against this backdrop, aluminum cables are gaining traction as a practical alternative. With their lower material costs, highly competitive performance, and reduced theft risk, aluminum cables offer project owners a viable way to ensure reliable system operation while controlling costs.

Benefits of Replacing Copper Cables with Aluminum Cables

Advantages of Aluminum Cable Metal Materials

Conductor: 12AWG~2000kcmil

Color: Black, red or other colors

Conductor: 14AWG~2000kcmil

Color: Black, red, white or other colors

Conductor: 1×10~400mm²

Insulation Color: Black

Jacket Color: Black

Conductor: 1×2.5~400mm²

Insulation Color: Black

Jacket Color: Black

· Low Material Cost of Aluminum Cables

One of the most significant advantages of using aluminum cables in PV projects is their cost-effectiveness. First, aluminum is more abundant and cheaper than copper, which directly translates into lower and more accessible material costs for large-scale solar installations. For PV projects affected by copper cable theft, replacing stolen copper cables with new ones could impose a heavy financial burden and even lead to project shutdowns. In contrast, aluminum cables allow project owners to restore systems at a much lower cost without compromising overall energy transmission efficiency. This price difference is particularly evident in utility-scale solar farms requiring kilometers of cabling.

Beyond initial material costs, aluminum cables can also reduce financial risks associated with potential future theft. Since aluminum has a lower resale value than copper, it is less attractive to thieves, helping to protect investments in the long term. In SUNKEAN's aluminum cable deployment projects, measures such as installing warning signs have effectively deterred copper cable theft. In summary, aluminum cables provide a practical and cost-effective solution for replacing stolen copper cables in PV projects. They not only minimize upfront costs but also help mitigate future theft risks.

· Lightweight Material of Aluminum Cables

Another key advantage of aluminum cables is their lightweight nature, with aluminum's density being approximately one-third that of copper. From a logistics perspective, lighter cables reduce transportation costs, especially for large-scale solar farms requiring several kilometers of cabling. Compared to copper cables, fewer trucks are needed to transport the same amount of cable, which not only lowers freight costs but also reduces the project’s overall carbon footprint.

The reduced weight of aluminum cables minimizes mechanical stress on support structures such as cable trays, conduits, and junction boxes. Over time, this enhances the installation's durability and reduces maintenance needs, further lowering operational costs.

For solar developers, EPCs, and O&M service providers, the lightweight of aluminum cables offers economic, logistical, and technical advantages unmatched by copper cables. This is also one of the main reasons why aluminum cables have become a practical alternative to copper cables in modern photovoltaic systems.

· Stable Material Price of Aluminum Cables

In addition to being cheaper and lighter, aluminum cables offer the important advantage of price stability. Unlike copper, which experiences significant price fluctuations due to global demand, limited mining output, and market speculation, aluminum exhibits more stable price trends. This stability provides solar developers and EPC contractors with greater predictability when budgeting and planning PV projects.

For project owners, stable aluminum prices mean fewer unexpected cost overruns and more reliable long-term financial planning. Whether for new projects or as replacements for stolen copper cables, aluminum enables investors to exercise better control over capital expenditures. This is particularly important in the solar industry, where profit margins are often thin, and financing typically relies on accurate cost forecasts.

Advantages of Aluminum Cables in Practical Installation

· Labor-Saving Handling of Aluminum Cables

For utility-scale solar farms requiring extensive cabling, the lighter weight of aluminum reduces strain on installers and minimizes the need for heavy machinery or specialized lifting equipment. Compared to copper cables, workers can more easily transport, bend, and connect aluminum cables, shortening installation time and reducing labor fatigue. In regions with high labor costs, this efficiency can lead to significant savings in total project expenditure.

Furthermore, aluminum cables are more flexible and easier to thread through conduits, trenches, or cable trays. This flexibility simplifies installation in complex layouts, such as ground-mounted PV systems with long cable runs or rooftop projects with limited space. The reduced handling difficulty also lowers the risk of damage during installation, helping to maintain cable integrity and system reliability.

· Aluminum Cables Reduce Maintenance Costs

In addition to lower material prices and easier handling, aluminum cables contribute to reducing long-term maintenance costs for PV projects. Maintenance is a critical factor in the overall lifecycle cost of solar installations, and the choice of conductor material can significantly impact the frequency and expense of maintenance.

First, PV power plants using aluminum cables are less likely to experience repeated theft incidents compared to those using copper cables. This directly reduces the risk of unexpected replacement costs and system downtime. Second, the lighter weight of aluminum cables imposes less mechanical stress on support structures such as cable trays, brackets, and connectors. Over time, this reduces wear and tear on these components, minimizing the need for repairs or reinforcements. Finally, SUNKEAN aluminum cable designs often incorporate advanced insulation and protective sheathing materials. These enhancements improve resistance to UV radiation, moisture, and temperature fluctuations, which are common challenges in outdoor PV environments. As a result, aluminum cables can maintain stable performance for up to 25 years, reducing the need for expensive replacements or comprehensive inspections.

Why Are Aluminum Cables an Ideal Solution for Retrofitting Photovoltaic Projects?

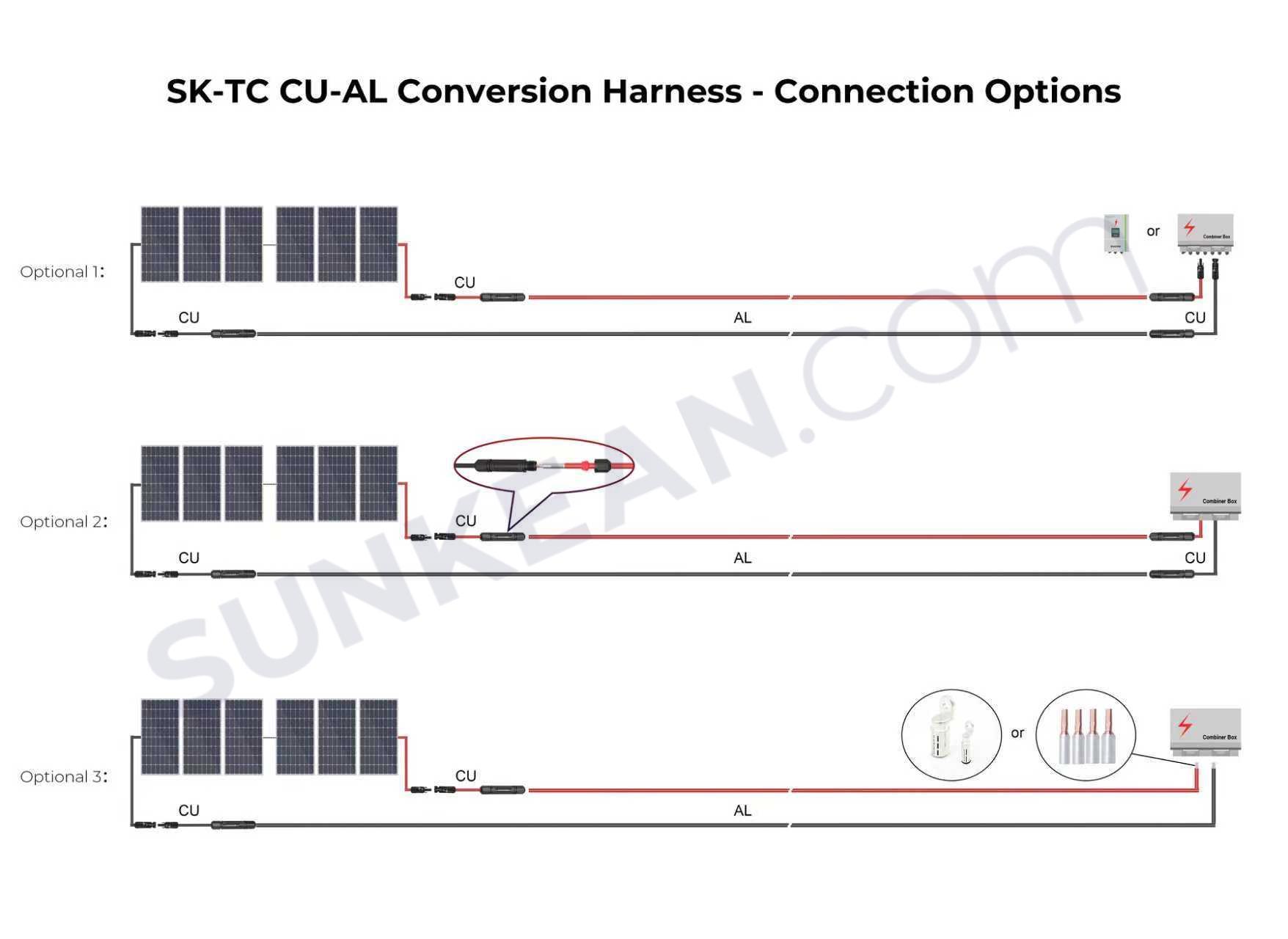

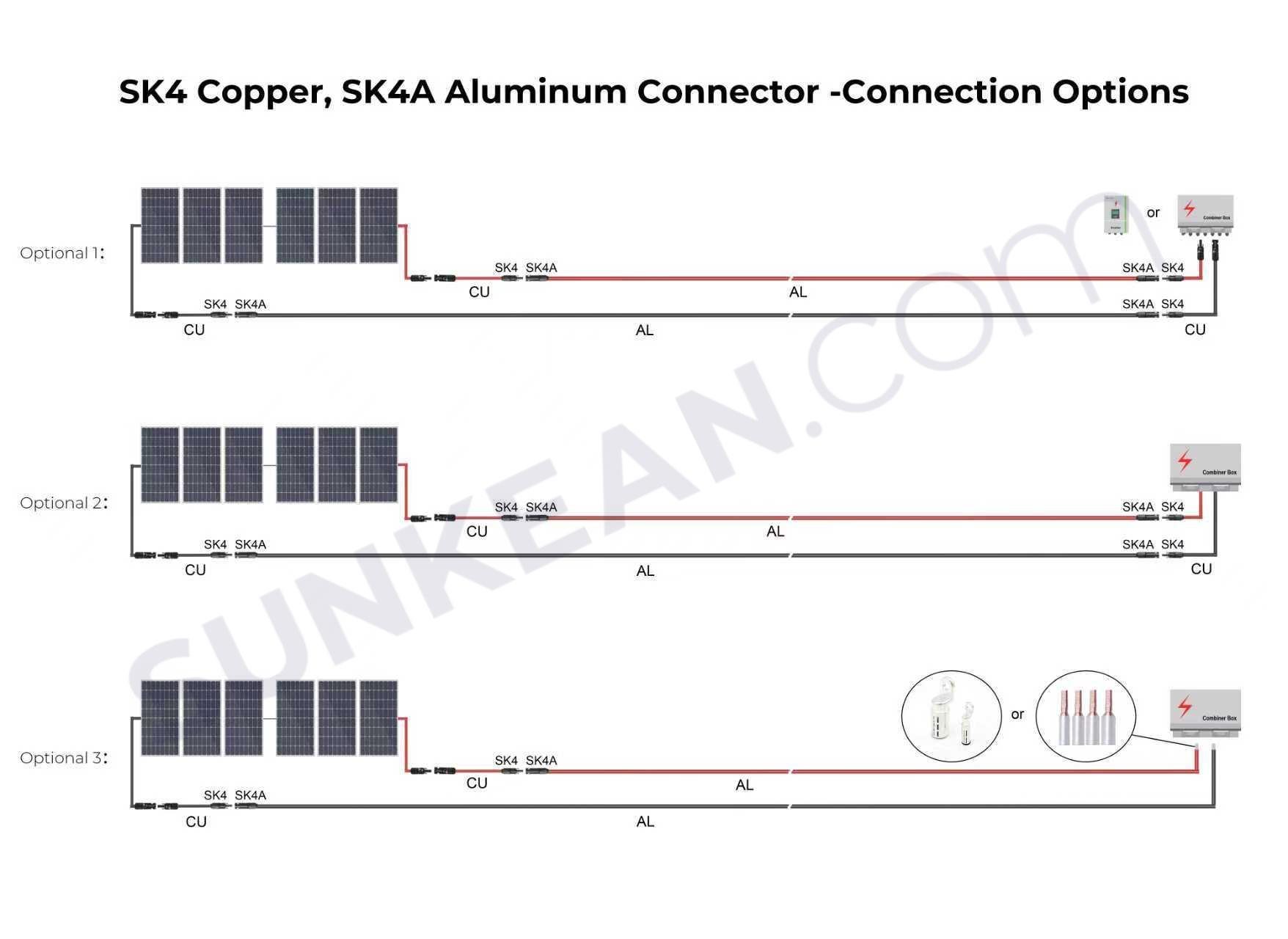

When retrofitting older PV projects, one of the biggest challenges is controlling costs while maintaining performance and safety. SUNKEAN aluminum cables offer a practical and cost-effective alternative that directly addresses these issues. First, as a cable manufacturer that has obtained the world's first DC2000V photovoltaic cable certification, SUNKEAN's aluminum cable products comply with TUV 2PfG 2642 and 2954 international certification standards. Building on this, the self-developed SK-TC copper-aluminum transition harnesses and SK4/SK4A copper-aluminum connectors provide mature and efficient aluminum cable replacement solutions for project retrofits.

FAQs: Aluminum PV Cables in Solar Projects

Q1: Can aluminum solar cables fully replace copper cables in existing PV projects?

Yes. With the right connectors and transition harnesses, aluminum cables can safely and effectively replace copper in both new and retrofit solar farms.

Q2: Are aluminum PV cables safe for long-term outdoor use?

Absolutely. With advanced insulation and protective sheathing, aluminum PV cables can operate reliably for over 25 years in harsh outdoor environments.

Q3: How much cost savings can aluminum cables bring compared to copper?

The project can achieve about 48% of the cost upon implementation, and we have achieved successful cases in South America and other regions.

Q4: What certifications do SUNKEAN aluminum cables meet?

SUNKEAN cables meet TÜV 2PfG 2642, 2954, and hold the world’s first DC2000V photovoltaic cable certification, ensuring international compliance.

Q5: Why are aluminum cables less likely to be stolen?

Because aluminum has a significantly lower resale value compared to copper, making it a less attractive target for thieves.